1 inch TF Electric water valve, drinking water automated valve, AC110v to 230V Electric motorised water valve, DN25 motorized water valve stainless for medicine production line

Features:

1. Miniature size -- fit for small systems.

2. Engineering plastic shell -- better for seal and protection.

3. All metal Gears -- means longer service life.

4. Low power consumption -- Limit switch cut off power to motor when fully open/close.

5. Manual override and on/off Indicator is safe& convenient.

6. IP67 Protection

Technical Parameters:

Product size: 1" (DN25)

Valve type: 2 Way

Maximum working pressure: 1.0MPa

Circulation medium: Cold/hot water,<50% glycol

Rated voltage: AC110V to 230V

Wiring control methods: CR2 02,CR303,CR401,CR502,CR703,CR704

Working current: ≤500MA

Open/close time: ≤5S

Life time: 100000 times

Valve body material: SS304

Actuator material: Engineering plastics

Sealing material: EPDM & PTFE

Actuator rotation: 90 degree

Max. torque force: 2 Nm

Cable length: 0.5m

Environment temperature: -15 ~ 50 centigrade

Liquid temperature: 2 ~ 90 centigrade

Manual override: Optional

Indicator: Optional

Protection class: IP67

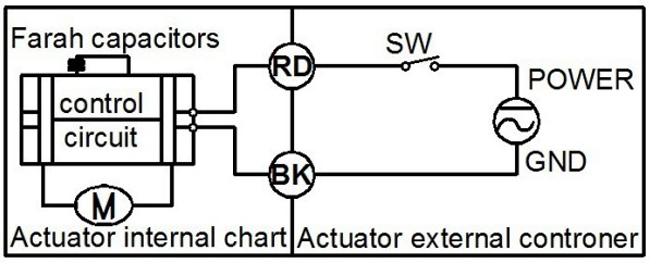

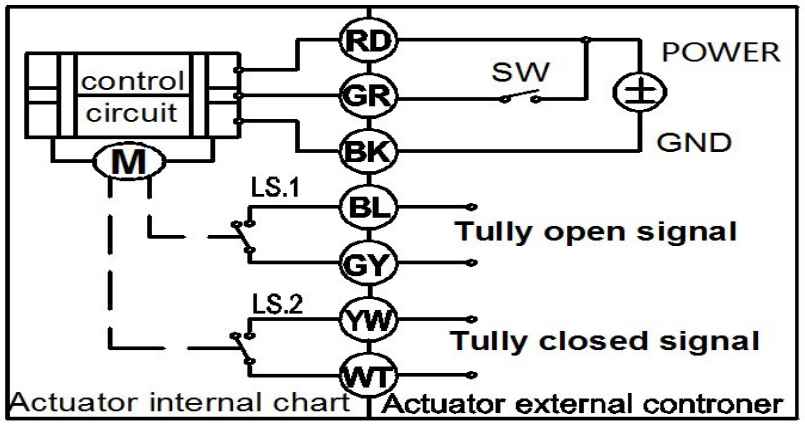

Wring diagram (CR2 02):

VALVE

OPEN:

Black wire connect to Negative and Red wire connect to positive, valve open.

VALVE

CLOSE: When

Red wire disconnects to power/power failure, valve close.

Remark: When VALVE

fully open/close, power supply to motor will be cut off automatically by limit

switch inside.

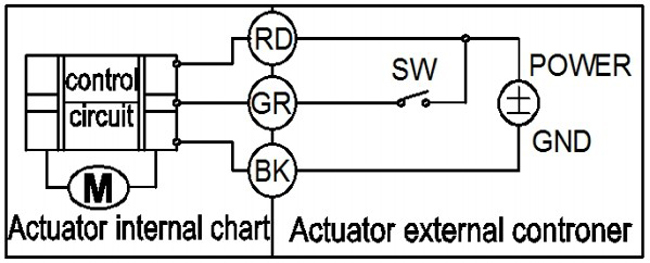

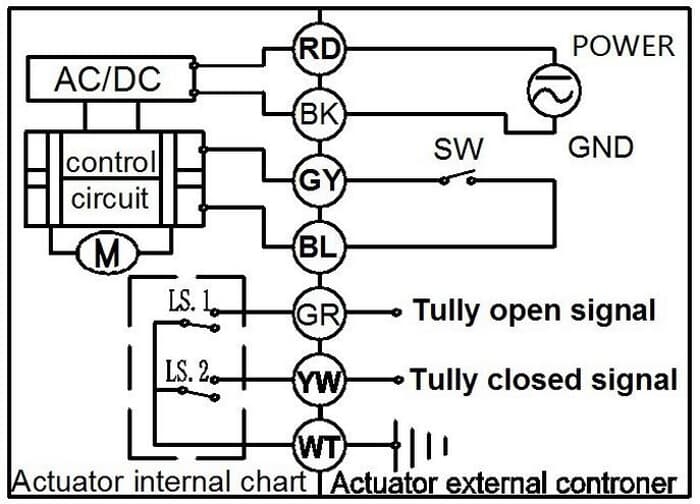

Wiring Diagram(CR3 03):

VALVE

OPEN:

Black wire connect to Negative and Red wire connect to

Positive, meanwhile

Green wire connects to Positive, valve open.

VALVE

CLOSE: Black

wire connect to Negative and Red wire connect to

Positive, meanwhile

Green wire disconnected, valve close.

Remark: When

valve fully open/close, power supply to motor will be cut off automatically by

limit switch inside.

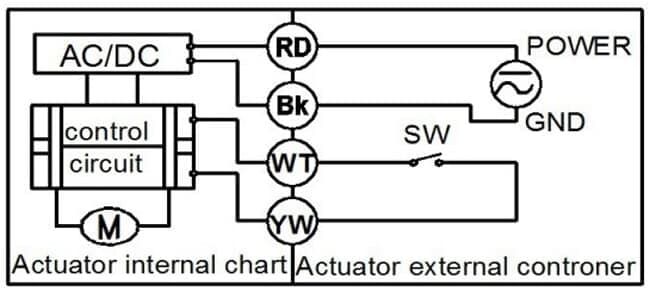

Wiring Diagram(CR4 01)

VALVE

OPEN:

Black wire connect to Negative and Red wire connect to

Positive, meanwhile,

White and Yellow wire connected, valve open.

VALVE

CLOSE: Black

wire connect to Negative and Red wire connect to

Positive, meanwhile,

White and Yellow wire disconnected, valve close.

Remark: When

valve fully open/close, power supply to motor will be cut off automatically by

limit switch inside.

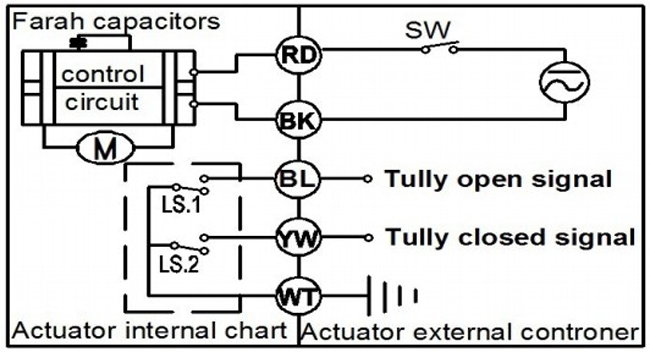

Wiring Diagram(CR5 02)

VALVE OPEN: Black

wire connects to Negative and Red wire connect to Positive, valve open.

VALVE CLOSE: When

black or Red wire disconnect to power/power failure, valve close automatically.

When valve fully

open, White and Blue wire get through

When valve fully

close, White and Yellow wire get through

Remark: When

valve fully open/close, power supply to motor will be cut off automatically by

limit switch inside.

Wiring Diagram(CR7 03)

VALVE

OPEN:

Black wire connect to Negative and Red wire connect to

Positive, meanwhile

Green wire connects to Positive, valve open.

VALVE

CLOSE: Black

wire connect to Negative and Red wire connect to

Positive, meanwhile

Green wire disconnected, valve close.

When

valve fully open, Blue and Gray wire get through

When

valve fully close, White and Yellow wire get through

Remark: When valve fully open/close, power supply to motor will be cut off automatically by limit switch inside.

Wiring Diagram(CR7 04)

VALVE OPEN: Black

wire connects to Negative and Red wire connect to Positive, meanwhile, White

and Yellow wire connected, valve open.

VALVE CLOSE : Black

wire connect to Negative and Red wire connect to positive, meanwhile White and

Yellow wire disconnected valve close.

When valve fully

open, White and Green wire get through

When valve fully

close, White and Yellow wire get through

Remark: When valve

fully open/close, power supply to motor will be cut off automatically by limit

switch inside.

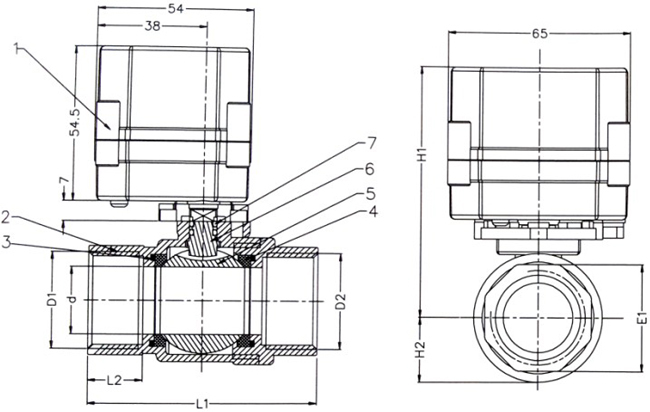

Electric valve dimension:

Main components material:

|

No. |

Name |

Material |

Qty |

|

1 |

Actuator |

PPO |

1 |

|

2 |

Body

cover |

SS304 |

1 |

|

3 |

O-ring |

FKM |

2 |

|

4 |

Sealing |

PTFE |

2 |

|

5 |

Ball |

SS304 |

1 |

|

6 |

Steam |

SS304 |

2 |

|

7 |

O-ring |

FKM |

2 |

Electric Valve Dimension:

|

Size (mm) |

D1/D2 |

d |

L1 |

L2 |

E1 |

H1 |

H2 |

|

TF8(1/4”)Electric valve |

1/4” |

10 |

51 |

12 |

21 |

82 |

14 |

|

TF10(3/8”)Electric valve |

1/4” |

10 |

51 |

12 |

21 |

82 |

14 |

|

TF15(1/2”) Electric valve |

1/2” |

15 |

63 |

14 |

25 |

83 |

17 |

|

TF20(3/4”) Electric valve |

3/4” |

20 |

72 |

17 |

31 |

87 |

20 |

|

TF25(1”) Electric valve |

1” |

25 |

81 |

18 |

38 |

95 |

24 |

Application

1. HVAC systems.

2. Water treatment.

3. Chemical process.

4. IC card water meters, heat energy meters, solar instrument.

5. The central air conditioning fan coil, fire sprinkler

3. Water saving irrigation, automatic control system, industrial mini automatic control equipment.

4. Agriculture Irrigation equipment

5. Drinking water equipment, Water heater, washing machine, AHW etc.

Strong Points:

1. Has compact size with smart shape, Perform reliably, has long life time.

2. The transmission system adopt new technology and made of metal gears with high output torque

3. Multi-angle assembly, convenience for different space allocation requirements.

4. Floating seal structure, no leak, suitable for heavy dirt and long time no action occasion.

5. Can replace the solenoid valve in the conditions that the solenoid valve can not be worked.

6. Varity of control methods, can both recognize the remote signal and feedback signal to the intelligent unit

7. Motor & manual integration designed with the indicator.

8. High protection class can be worked in moist conditions.

9. Acquired CE certification and ISO certification

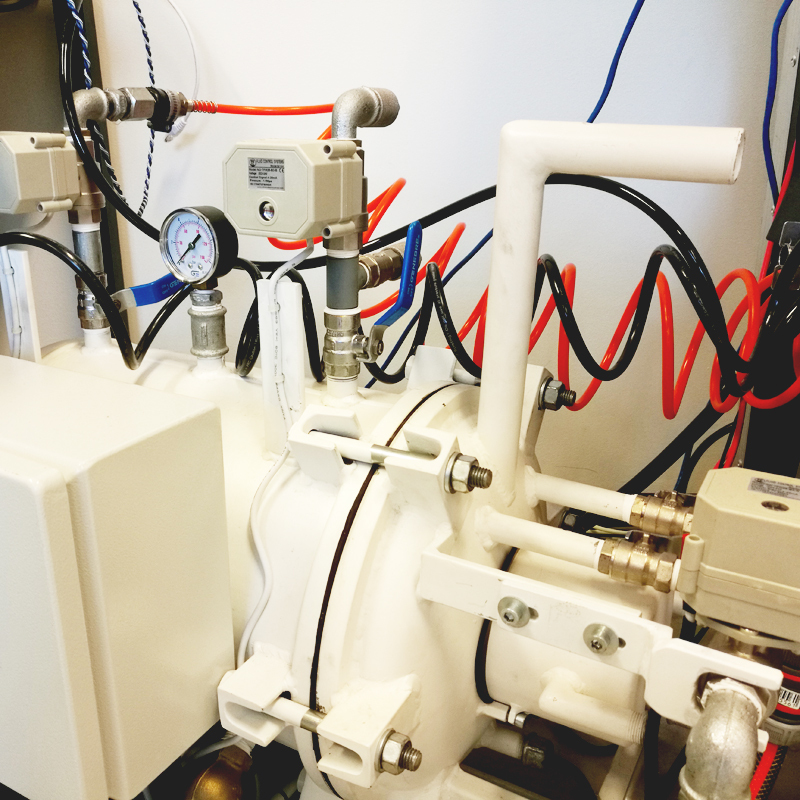

Product Display

Shipment:

When

you place an order, please choose a shipping method and pay for the order

including the shipping fee. We will send the goods within 7 days once the

payment is completed. We do not guarantee delivery time on all international

shipments due to difference in customs clearing time in different countries. Please

note that the shipping cost does not include any import tax. Buyers are

responsible for customs duties.

Returns:

We

do our best to serve our customers the best that we can. We will refund you if

you return the goods within 15 days from your receipt of the goods for any reason.

However, the buyer should make sure that the goods returned are in their

original conditions. The buyer will be responsible for the shipping fee to

return the goods.

Warranty

& Maintenance:

We

offer 1- month free replacement. Buyers may request replacement within 1 month

from your receipt of the product for defect reason. The buyer should return the

product in the original conditions to us and should bear the sipping costs for

return.

We

also provide 12-month free maintenance. The buyer should return the product in

the original conditions to us and should bear the shipping costs for return. If

any part is required to be replaced the buyer should also pay for the costs of

the parts to be replaced. Before returning the items, please confirm the return

address and the logistics method with us. After you give the items to the

logistic company, please send us the tracking number. As soon as we receive the

items, we will repair or exchange them ASAP.

Feedback:

Your

satisfaction and positive feedback is very important to us. Please leave

positive feedback and 5 stars if you are satisfied with our products and

services.

If you have any problems with our items or services, please feel free to contact us first before you leave negative feedback. We will do our best to solve any problems and provide you with the best customer services.

Tags: dn8 electric automated water valve spring return, dn8 electric automated water valve, dn8 electric valve, dn8 electric valve manufacturers

If you want to know products, we have: dn10 electric actuated water valve power off return type , dn15 electric power failure return valve , dn8 mini electric ball valve 3-way

- Voltage:

- AC110V to 230V

- Size:

- 1"(DN25)

- Valve body material:

- SS304

More Products

Your cart is currently empty.

USD

USD